Service Tel:0769-82327388

Mobile:150 1267 9411

Email:sunny.lv@uk-st.com

Address:No. 3339 Chengyang Road, Weitang Town, Xiangcheng District, Suzhou City, Jiangsu Province

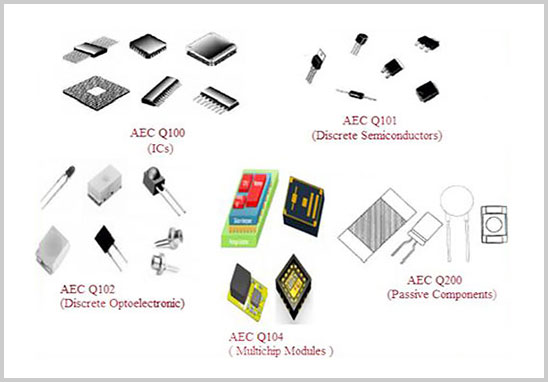

AEC-Q, as an international standard for testing electronic components at the vehicle specification level, has become a symbol of the quality and reliability of vehicle components. AEC-Q certification testing of electronic components plays an important role in improving product competitiveness and quickly entering the supply chain. Jiangsu Yueke Testing is a professional third-party AEC-Q certification and testing institution, which can provide certification and testing services for vehicle specification level electronic components AEC-Q100, AEC-Q101, AEC-Q102, AEC-Q103, AEC-Q104, AEC-Q200, and can issue nationally recognized third-party CNAS testing reports.

Integrated Circuit (IC) | Automotive Discrete Devices | Discrete Optoelectronic Semiconductors | MEMS Sensors | Multichip Modules | Passive Devices

AEC-Q100 Certification Specification for Chip Stress Test

AEC-Q101 Certification Specification for Stress Test of Discrete Components

AEC-Q102 Specification for Reliability Verification Test of Automotive Discrete Optoelectronic Semiconductor Components

AEC-Q103 Certification Specification for Automotive Sensor Stress Testing

AEC-Q104 Specification for Reliability Testing of Multi chip Modules for Vehicles

AEC-Q200 Certification Specification for Stress Test of Passive Components (Passive Components)

Parameter testing: functional verification, electrical performance parameters, optical parameters, thermal resistance, physical dimensions, avalanche tolerance, short circuit reliability, etc;

Environmental stress test: high temperature work, high temperature reverse bias, high temperature grid bias, temperature cycle, high temperature storage, low temperature storage, high pressure cooking, HAST, high temperature and high humidity reverse bias, high temperature and high humidity work, low temperature work, pulse work, intermittent working life, power temperature cycle, constant acceleration, vibration, impact, drop, coarse and fine leak detection, gas tightness, salt spray, condensation, hydrogen sulfide gas corrosion, mixed gas corrosion, etc;

Process quality evaluation: DPA, terminal strength, solvent resistance test, welding heat resistance, weldability, shear force, lead-free test, flammability, flame retardancy, plate bending, beam load, etc;

ESD:HBM、CDM、LU。

1. As an independent third-party testing, inspection and certification laboratory, we adhere to the service tenet of justice, science, accuracy, professionalism, efficiency, high quality and innovation to serve customers wholeheartedly and become a partner that is highly relied on by the world.

2. Provide free factory inspection guidance and a confirmation inspection report every year.

3. Value added services: consulting services, technical training, structure review, pre-test, countermeasures and rectification.

4. The insurance coefficient is large, including case and pre-test services, which can improve the success rate of certification, greatly reduce the retest risk and certification cost, avoid witnesses, and shorten the certification cycle.

5. It has been authorized by several certification bodies to provide you with efficient one-stop multinational certification services.

If you have any comments or suggestions on our products or services, you can give us feedback through this channel. We will reply to your message as soon as possible!